NEWS

3D printed aluminum parts

Writer: admin Time:2022-02-25 17:46 Browse:℃

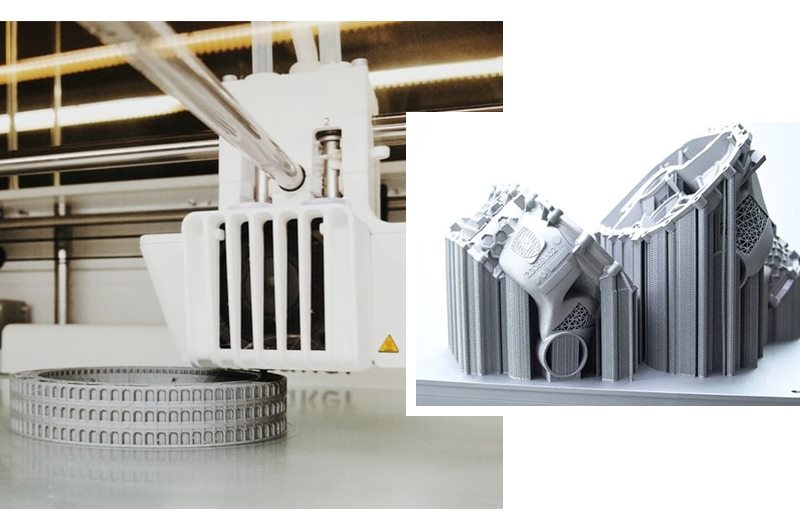

In recent years, additive manufacturing has become a new buzzword sweeping the whole industry. This technology, commonly known as 3D printed aluminum parts, is developing rapidly. It is changing the manufacturing mode of things and has the potential to completely change the manufacturing industry.

Although many people believe that 3D printed aluminum parts manufacturing is a cheap, fast and repeatable way to make plastic objects, many other materials are also being tested. This includes metals such as aluminum. People pay more and more attention to the possible use of aluminum alloy in additive manufacturing applications.

What is additive manufacturing?

The term "3D printed aluminum parts" refers to many processes that involve joining or curing materials under the guidance of a computer to form a three-dimensional object. Because materials are added together through a layer by layer process, it is also called additive manufacturing. This is contrary to the traditional manufacturing method, in which the material is removed from the object (so-called reduced material manufacturing) or poured into the mold.

Although this technology has existed since at least the 1990s, new advances in accuracy, repeatability and material selection have made 3D printed aluminum parts commercially viable as an industrial production technology. One of the main advantages of 3D printed aluminum parts is the ability to create very complex shapes. Moreover, because the parts are produced based on digital 3D model or CAD file, each output part is almost the same. Costs also continue to fall, making it more feasible.

How is 3D printed aluminum parts used in manufacturing?

At present, the commonly used aluminum powder is likely to be the component of Hypereutectic casting alloy. They consist of very small spherical powder particles. The particles range in size from 10 to 75 microns (thousandths of a millimeter). It is important to note that for additional manufacturing processes, the particles need to be as close to spherical as possible to maintain proper flow during the process and ensure that the finished parts have sufficient mechanical properties.

Not all aluminum additives are manufactured with powder as the main material. Aluminum wire is also popular and can actually be used with a variety of alloys. The wire rod forms the final part through an electron beam emitter, which deposits aluminum layer by layer from the wire rod raw material. This is the faster method among the current feasible methods, and the size of the final part is only limited by the size of the vacuum chamber.

New developments in additive manufacturing provide us with a preview of the future prospects of 3D printed aluminum parts. This method is called nano functionalization and is being tested on popular alloys such as 6061 and 7075. The nano functionalized aluminum powder is fed into the machine and then heated with a laser until the desired shape is formed. One of the main advantages of this technology is that due to the filling of nanoparticles as nuclear sites, the final structure retains the strength of the alloy without cracking.

3D printed aluminum parts has been widely used in many key industries, such as aerospace, national defense and medical applications.

CNC MACHINING SERVICES

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan