NEWS

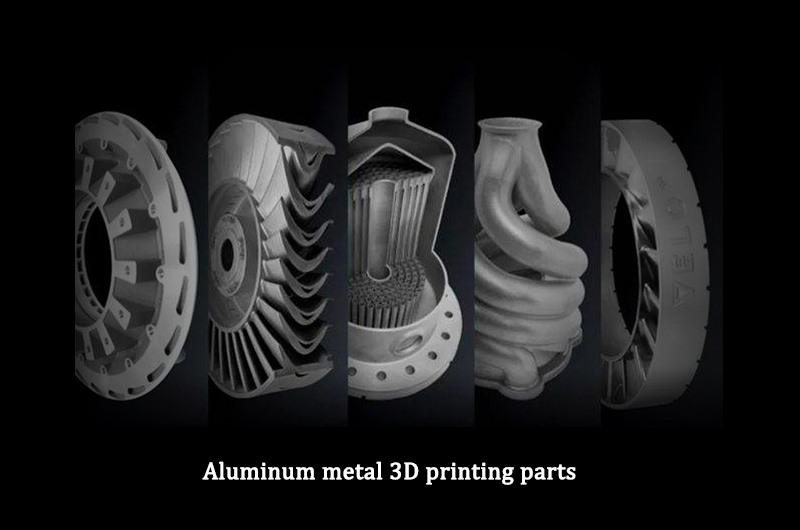

Aluminum metal 3D printing parts

Writer: admin Time:2022-01-11 17:57 Browse:℃

What is Aluminum metal 3D printing parts?

Aluminum metal 3D printing parts produces parts by fusing together metal powder layer by layer to form a metal part. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedoms afforded by 3D printing. Aluminum metal 3D printing parts can produce complex designs including lattices and topology-generated structures, both which are impossible to manufacture via traditional CNC machining.

Advantages of Aluminum metal 3D printing parts :

Aluminum metal 3D printing parts is advantageous because it can produce high-performance parts that are suited for a range of end environments. Aluminum metal 3D printing parts are isotropic, meaning they have even, multi-directional strength, and have the superior mechanical properties .

Aluminum metal 3D printing parts can also be used to combine multiple assembly components into one part. This typically results in a stronger structure by reducing the points of failure introduced by threads and inserts.

With Aluminum metal 3D printing parts, CAD file information is sent directly to a printer meaning parts are typically cheaper and faster than producing machined metal parts. Machined metal parts have overhead costs like tooling set-up and longer machining time. Most Aluminum metal 3D printing parts can be turned around in less than a week.

CNC MACHINING SERVICES

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan