NEWS

Aluminum metal stamping parts

Writer: admin Time:2021-08-20 17:15 Browse:℃

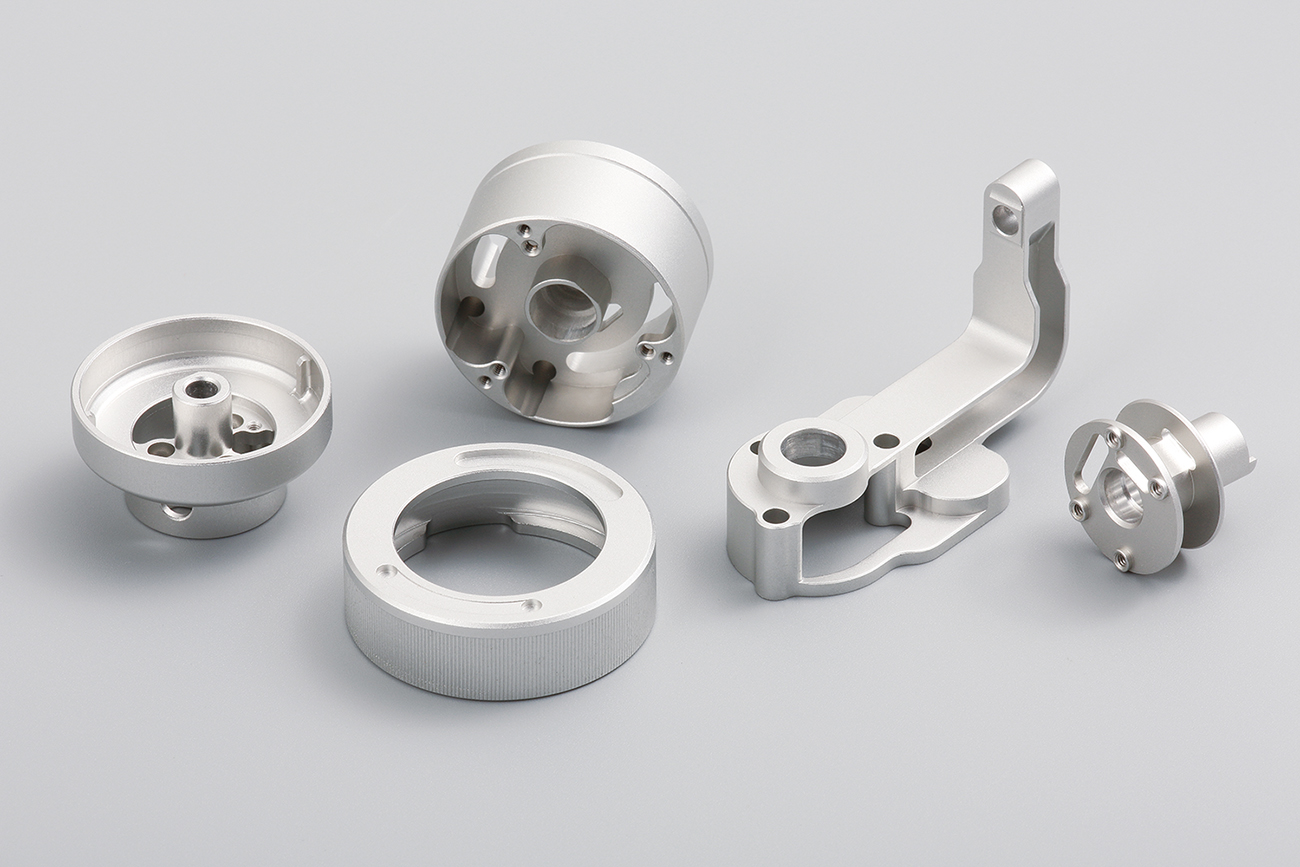

Aluminum metal stamping parts is a silvery-white metal that has comparable strength to carbon steel but at roughly one-third the density. This alloy is very ductile and malleable making it ideal for precision stamping processes.

Aluminum metal stamping parts can also be anodized to enhance surface hardness and corrosion resistance in challenging environments. Common Aluminum metal stamping parts uses include:

1: Spun parts, chemical equipment, and anodized parts

2: Aircraft & screw machine components

3: Hardware, furniture & cooking utensils

4: Sheet metal ductwork

5: Marine hardware, architectural structures & aerospace components

6: Extruded architectural structures & pipes

Features and advantages of Aluminum metal stamping parts include:

1: Ductility: Aluminum metal stamping parts has a low melting point that allows flexible formation throughout product design, making it ideal for the power storage, beverage container, battery, consumer electronics, pharmaceutical and decorative packaging industries.

2: Reflectivity: Often used for solar technology and similar applications, Aluminum metal stamping parts is reflective of light and heat.

3: Recyclability: Aluminum metal stamping parts is easily recycled without deterioration, making it highly sustainable.

4: Corrosion-resistance: Aluminum metal stamping parts generates a natural oxide coating, and is tolerant to moisture and most chemicals.

5: Lightweight strength: Aluminum metal stamping parts has an excellent strength-to-weight ratio, and is especially strong when combined with other metals. This is critical to the automotive and aerospace industries, where excess weight elimination improves fuel economy.

CNC MACHINING SERVICES

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan