NEWS

Anodized CNC aluminum parts

Writer: admin Time:2021-06-11 18:11 Browse:℃

In order to overcome the Anodized CNC aluminum parts surface hardness of aluminum alloy, wear resistance and other aspects of the defects, expand the scope of application, prolong the service life, surface treatment technology has become an indispensable part of the use of aluminum alloy.Metal oxide film changes the surface state and performance, such as surface coloring, improve corrosion resistance, enhance wear resistance and hardness, protect the metal surface, etc.

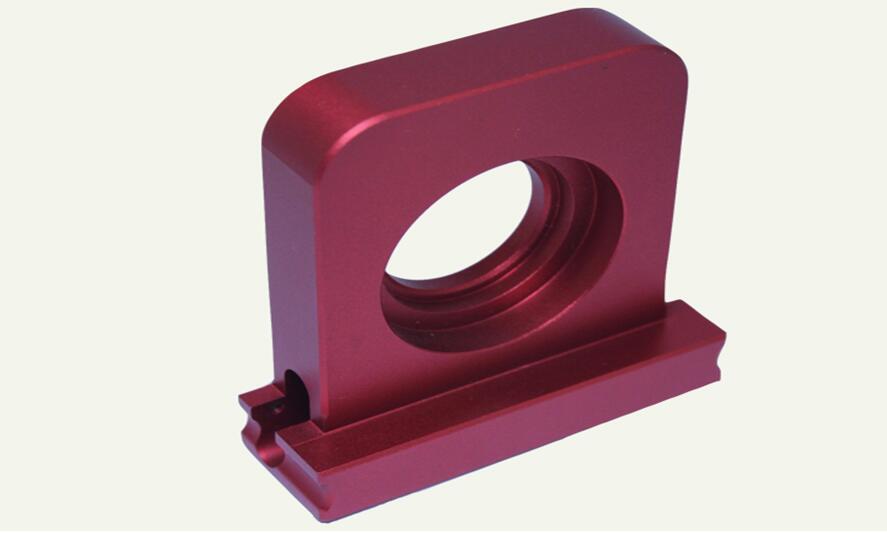

The product is Anodized CNC aluminum parts, customized for customers of optical instrument parts, CNC milling processing, after the completion of the surface according to customer requirements for anodic oxidation treatment.

Advantages of Anodized CNC aluminum parts :

1: improve the corrosion resistance in fact, aluminum alloy is a kind of corrosion resistant metal, because aluminum is very active, especially easy to react with oxygen in the air to produce alumina..

2: improve the wear resistance of aluminum profile base material is particularly easy to scratch and wear, after all, the hardness of aluminum alloy can not be compared with steel.

3: decorative aluminum products surface coloring

4: improve the insulation

CNC MACHINING SERVICES

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan