NEWS

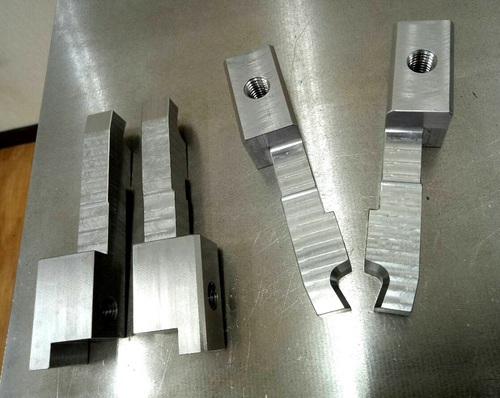

Custom CNC machining parts

Writer: admin Time:2020-11-27 16:00 Browse:℃

Custom CNC machining parts is to fix the blank and use a high-speed rotating milling cutter to cut on the blank to cut out the required shapes and features. Traditional milling is used more often for simple shapes / features such as contours and grooves. Custom CNC machining parts can process complex shapes and features. The milling and boring machining center can perform three-axis or multi-axis milling and boring processing for processing, molds, inspection tools, tire tools, thin-walled complex curved surfaces, artificial prostheses, blades, etc. When choosing the content of Custom CNC machining parts processing, the advantages and key functions of Custom CNC machining parts should be brought into full play. Five-axis CNC machining is a type of milling.Five-axis CNC machine tools are high-tech, high-precision machines that are specially used to process complex curved surfaces. This machine tool system has a significant influence on the aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment and other industries of a country. Chalco aluminum has such high-precision equipment, and provides professional support for enterprises and government agencies seeking high quality and high requirements around the world. Five-axis CNC includes cradle, vertical, horizontal, NC table + NC indexing head, NC table + 90 ° B axis, NC table + 45 ° B axis, NC table + A axis, two axis NC Spindle and so on.

(1) Double swing head (+ A, + C)

(2) Dip type swing head type (+ B, + C cutter)

(3) Double turntable type (NC work bench)

(4) Prone type work bench (+ B, + CNC work bench)

(5) One pendulum and one rotation form (+ A, NC work bench )

CNC MACHINING SERVICES

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan