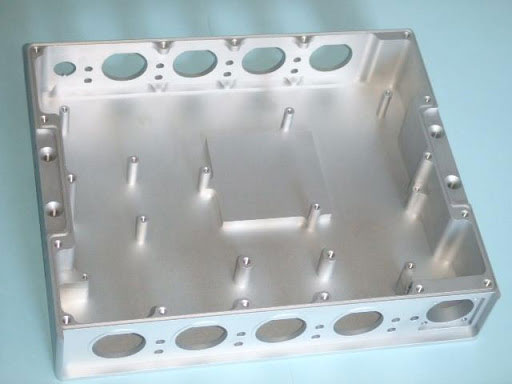

CNC MACHINING PARTS

6061 aluminum CNC parts

- Skype: chalcoaluminum

- Phone: 86 17344894490

- Tel: 86 17344894490

- Email: business@chalcoaluminum.com

6061 is a high-quality aluminum alloy product produced by heat treatment and pre drawing process. Although its strength can not be compared with 2XXX system or 7xxx system, its magnesium and silicon alloy have many characteristics, such as excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness, no deformation after processing, compact and defect free material, easy polishing, easy coloring film and oxidation effect Excellent and other excellent features.

Main Attributes of 6061 aluminum CNC parts:

- Excellent corrosion resistance to atmospheric conditions & good resistance to sea water

- Very good weldability although reduced strength in weld zone (can be re-heat treated & artificially aged again to restore strength)

- Medium fatigue strength

- Available in sheet, plate & extrusions

- Good surface finish

- Good toughness and structural strength

- Good machinability

| Composition of 6061 aluminum CNC parts | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | Others | Alu | |

| Each | Toal | ||||||||||||

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

Typical applications of 6061 aluminum CNC parts include aerospace fixture, electrical fixture, communication field, and also widely used in automatic mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carrier, etc.

Reasons to Choose Chalco:

- ISO 9001:2015 quality assurance

- Consistent high quality machined parts

- Reliable delivery dates

- Exceptional customer service and communication

- Machining design advice

- Extensive experience in our field

PREVIOUS:5251 aluminum CNC parts NEXT:6063 aluminum CNC parts

CNC MACHINING SERVICE

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts