NEWS

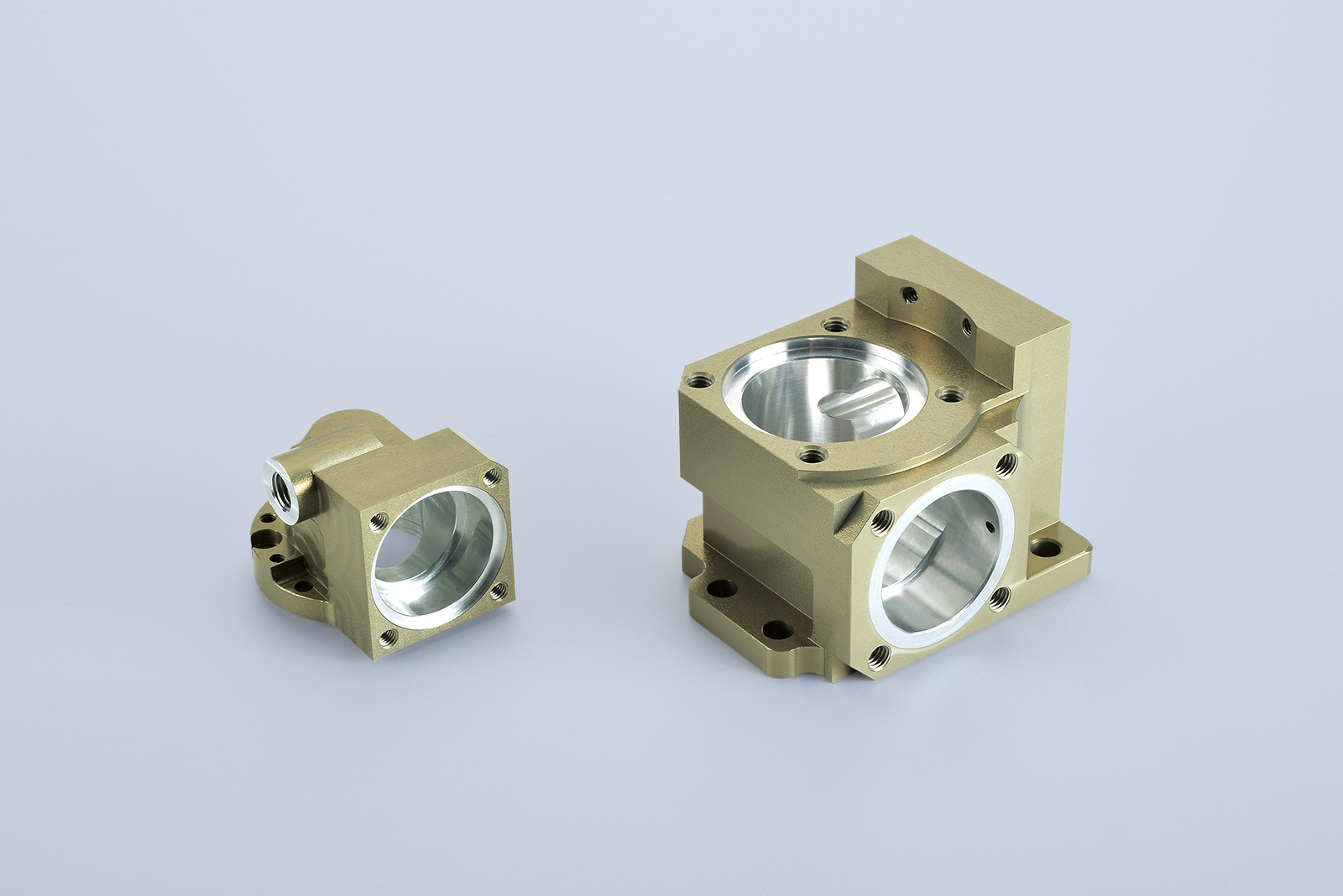

2014 T6 machining forged cnc aluminum parts

Writer: admin Time:2021-08-07 08:52 Browse:℃

2014 T6 machining forged cnc aluminum parts is Al-Cu-Mg-Si high strength forged aluminum alloy, which can be strengthened by heat treatment. The chemical composition of the alloy is similar to 2A14 aluminum alloy, with high strength and good thermal working properties, easy to forge. The performance and 2A14 is basically comparable. Due to the high copper content, the alloy has poor corrosion resistance and has the tendency of intergranular corrosion and stress corrosion. Its weldability is good and cutting performance is good.

For the manufacture of high strength, high hardness and high load bearing wheel rim, such as wheel rim, truck frame and suspension assembly, rocket booster fuel tank and structural parts, etc.

2014 T6 machining forged cnc aluminum parts is through the use of advanced CNC machining center spindle axis and the vertical table Settings (by changing different milling head can also be parallel) machining centers, milling, boring, drilling, drilling, expansion, ground), tapping screw, processing a variety of functions, mainly suitable for processing various precision components, widely used in automation equipment, aerospace, printing, packaging, textiles, military industry, mold and other CNC precision aluminum processing industry.

Chalco Aluminum focus on design and manufacture all kinds of 2014 T6 machining forged cnc aluminum parts , and according to user needs processing a variety of machining forged cnc aluminum parts .

CNC MACHINING SERVICES

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts

CONTACT US

Phone: 86 17344894490

Email: business@chalcoaluminum.com

Add: No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan